Cold winter, the toilet is really a headache, the cold toilet seat, let a person really uncomfortable. But the smart toilet, which has a seat heating function, solves that problem by keeping your butt and, more importantly, your heart warm even during the cold winter months.

The smart toilet has the function of cleaning, how does the hot water of cleaning come?

The hot water of intelligent closestool has namely hot type and store hot type two kinds.

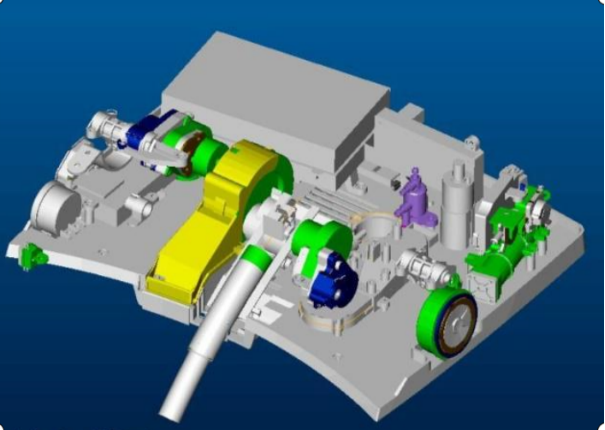

Frequency conversion instant namely hot intelligent closestool: namely open and play, more energy saving; Running water is hot and more sanitary; The water outlet temperature is more stable, the water temperature control temperature accuracy is higher, even in the winter days continuous cleaning can ensure the water outlet temperature constant, better comfort.

Heat storage type intelligent toilet: stainless steel heating tube, low cost; 1.0L water tank, large volume; Preheating insulation, more electricity consumption; There is no need to change the water manually for a long time, otherwise the water storage sanitation cannot be guaranteed; The water outlet temperature fluctuates greatly, and the temperature difference between front and rear is 3-4℃. Especially in cold winter, the continuous cleaning water outlet temperature is low, and the comfort is poor.

Frequency conversion instant namely hot intelligent toilet because of saving electricity, sanitation, hot water temperature constant, comfortable, more popular. Based on the advantages of instant smart toilets, materials are key. The material shall comply with all test requirements of the product. Materials should not only have high mechanical strength, high temperature and low temperature resistance, but also good dimensional stability.

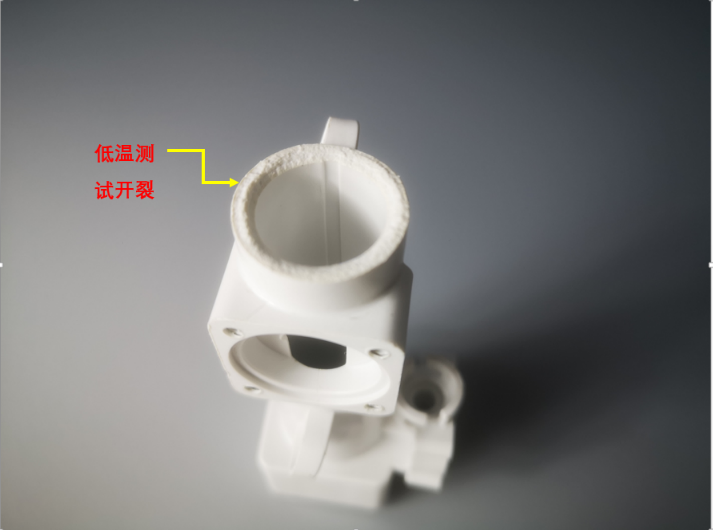

The PBT flame retardant fibre-adding material used for instant thermal components has cracked during the low temperature test after water injection. To solve this problem, Jiyou new material developed PA reinforced flame retardant V0 material through the design of material formula.

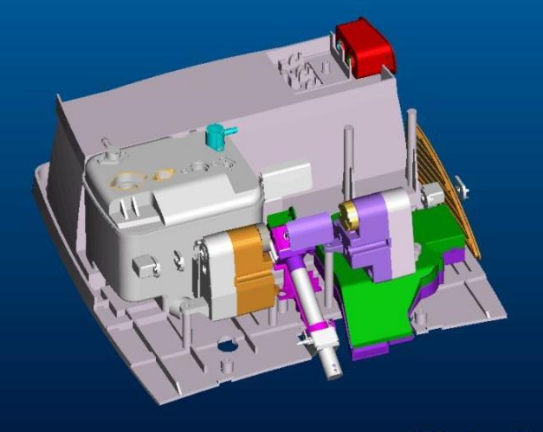

The following is the experimental test of the instant thermal component products using PA enhanced flame retardant V0 material:

First, after the product has been tested for incoming pressure resistance, the appliance has no leakage, obvious deformation and other abnormalities, and the product functions normally.

Second, the product was first subjected to three cycles of high and low temperature storage test, followed by a high temperature load test, then a low temperature load test, and finally a constant humidity and heat test. After all the cold and hot cycle tests, there is no cracking or serious deformation of the parts. All basic functions of the product are normal.

Third, after the product heat aging test, check the outside surface of the product without plastic cracking, serious deformation, continue to be placed at room temperature, and then the water resistance test. After test: the whole machine works normally, without water leakage, deformation and other abnormal phenomena.

Fourth, the product is heat-resistant and fire-resistant. During the test, there is no ignition or gradual heating of the product.

After the above tests, PA reinforced flame retardant V0 material of instant component products, can meet the requirements of instant component products detection.

PA reinforced flame retardant V0 material features:

The flame retardant effect can reach UL-94 0.8mm V-0

Good dimensional stability

Low warp

Surface floating fiber effect is good

It has good impact performance at low temperature.

PA reinforced flame retardant V0 material can be used not only in instant thermal components, but also in electrical boxes, kettle lines and other products.